TOP

TOPRelated Products

Related Cases

Wet electric and wet dust removal project of Steel slag of Hebei Handan Zhongban Steel Mill

Shanxi Hongda steel slag wet electric Dust removal project

Shanghai Bulannuo Industrial packaging materials online monitoring project

China Tobacco Ningxia Hongde VOCs exhaust gas treatment project

Shanghai Hengjie Wood Industry VOCs waste gas treatment project

Pingyao Paper Mill desulfurization, denitration and dust removal EPC project

Lihuang patent technology environmental protection equipment power raw material waste gas treatment!

High-tech enterprise

The sky is bluer and the water is greener and we have been trying

In 2022, Shanghai Lihuang Environmental Protection Engineering Co., LTD. (hereinafter referred to as "Shanghai Lihuang") enters its eighth year of rapid development. After nearly ten years of hard work, Shanghai Lihuang adheres to the noble mission of "committed to environmental protection, comprehensive development of sea, land and air", and has at least more than 1000 successful cases in technical design, production and manufacturing, quality inspection and project management in accordance with strict management system.

01 Environmental protection equipment factory go to the scene

The workers are working meticulously!

Recently, in Shanghai li Huang sales, technology, production and other departments to cooperate, according to the requirements to complete the production task of the original power of Zhangjiakou, successfully passed the user fine, harsh plant acceptance, production schedule and product quality to meet the needs of customers. On March 15, The first phase of Yuanshi's treatment equipment (pre-treatment filter +5000 air volume three-room RTO) was successfully loaded and shipped, and will go to the site of Hebei Yuanshi project for installation.

In this project, the client compared with many domestic enterprises, and finally decided to cooperate with Shanghai Lihuang after a thorough investigation of its design capacity, manufacturing capacity, quality control and after-sales service. Shanghai Lihuang also lived up to the customer's trust, mobilized the factory staff to work overtime to ensure production, enhance awareness to ensure quality, and finally delivered a satisfactory answer to the customer as scheduled.

02 Analysis of technical difficulties and advantages

01Process difficulty analysis

The pollutant in this project is DMAC, which generates nitrogen oxides after oxidation reaction. The concentration of NOx, the reaction product, is about 600mg/m3.

SCR technology, namely selective catalytic reduction technology, is one of the mainstream flue gas denitration technology. In the temperature range of 280-450℃ in the furnace, under the action of catalyst, NH3 or urea can selectively reduce NOx in flue gas, basically does not interact with O2 in flue gas, so SCR flue gas denitrification technology was developed.

02Lihuang technology advantage

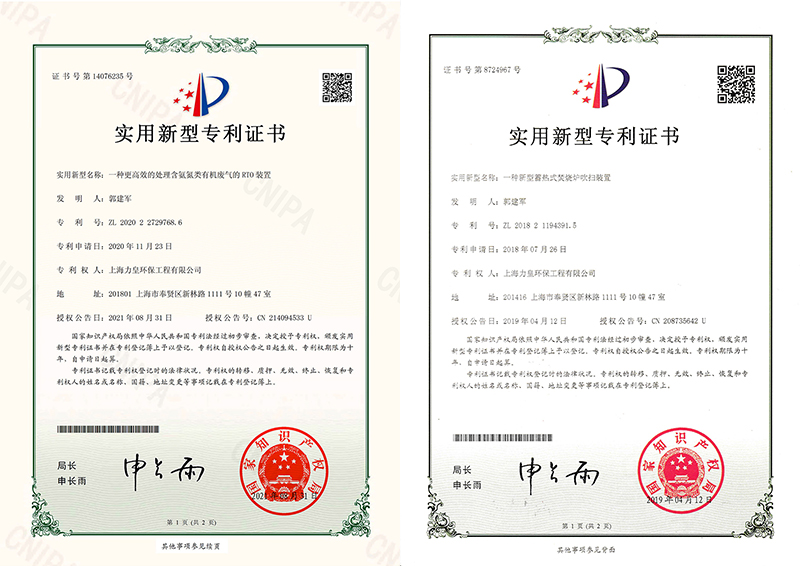

Three-chamber RTO: A more efficient RTO device for the treatment of organic waste gas containing ammonia nitrogen (Patent No. 2020227297686), its technology is specifically designed to solve the waste gas component produced by production and processing that ordinary three-chamber RTO cannot handle: DMAC (dimethyl acetamide).

Backblowing system: A new regenerative incinerator purging device (patent No. 2018211943915), its technology can reduce the overall energy consumption by 5%, high backblowing efficiency, avoid untreated other emissions to improve purification efficiency.

Safety protection system: RTO system fan, combustion fan explosion-proof + frequency conversion, the whole combustion system adopts imported brand, to ensure safety and reliability in the whole operation process.

In the next step, our company will further strengthen product innovation and research and development efforts, improve scientific and technological innovation ability, research and development and production of more high-quality, high-tech products, to make more contributions to the development of China's environmental protection equipment industry!

03RTO advantage of lihuang three rooms

It can deal with almost all organic waste gas, especially suitable for the incineration of hydrocarbons with low organic content; Compared with the traditional catalytic combustion, direct combustion thermal oxidation technology, the treatment of large air volume, medium and low concentration of industrial organic waste gas effect is remarkable, and has high purification efficiency (up to 99%), high thermal efficiency (up to 95%), low operating costs;

■ It can adapt to the fluctuation of organic composition and concentration in the exhaust gas, and is not sensitive to a small amount of dust and other solid particles in the exhaust gas, and when the VOCs concentration reaches more than 1500mg/m3, it can achieve self-sustaining combustion without adding combustion-supporting fuel;

■ Heat storage carrier for heat exchange, heating speed, low temperature heat exchange efficiency, low smoke exhaust temperature, remarkable energy saving effect; The higher heat recovery significantly reduces the amount of supplementary fuel and greatly reduces the production and operation costs;

■ The overall temperature in the furnace gradually increases and distributes evenly, the combustion temperature is high, the speed is fast, the noise is low, the flue gas stays in the furnace at high temperature for a long time, which effectively reduces the production of NOx;

■ The pressure loss of the whole processing device is small (generally <3000Pa), organic sediment can be periodically removed, heat accumulator can be replaced, and the service life of the device is long.

In the national advocate energy conservation and environmental protection, vigorously develop circular economy today, Shanghai Lihuang environmental protection equipment products with its good product performance and excellent energy-saving effect, become the majority of customers to solve the problem of waste gas emission reduction. Shanghai Lihuang environmental protection equipment has a perfect process research and development and after-sales system, and constantly bring forth the new, optimize the product line. At the same time, Shanghai Lihuang is committed to developing the international market, the products have been sold to Serbia, Iran, India, Singapore, Taiwan and other more than 10 countries and regions.