TOP

TOPLihuang engineering quality management node all-round control!

Shanghai Lihuang Group Shanxi manufacturing base

Shanghai Lihuang Environmental Technology Group Co., Ltd. is a professional environmental protection company engaged in desulfurization, denitrification and dust removal, VOCs organic waste gas treatment, VOCs online monitoring system, environmental protection agents, research and development, design and manufacturing, engineering contractor and facility operation as one of the high-tech enterprises.

01 Drawing Design

An environmental protection equipment project for waste gas treatment needs to be communicated through design, procurement, manufacturing, construction and other links from preliminary planning to implementation. How to ensure the high reducibility of the design drawing to the actual completion effect is the test of the control ability of the technical department.

Engineers in the technology department should first design according to the actual needs. Applicability should be considered in the design process, and economy should also be considered from the perspective of the owner. Secondly, according to the installation position and shape of equipment, pipeline direction, bridge position and other field information, production equipment processing drawings and project process diagram are issued.

The technical department spares no effort to control the effect. In the implementation process of each project, all departments make use of frequent and efficient communication to build the foundation to guarantee the satisfaction of Party A.

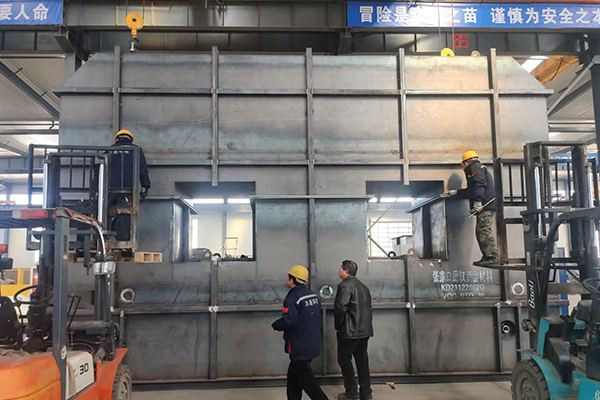

02 Environmental protection equipment manufacturing

From the system construction of the new era of environmental protection equipment quality management system actively, promote comprehensive quality management, full, whole process, the omni-directional and diversified methods, in order to deliver the satisfaction to the owner, to achieve emission standards as the goal, the whole process of implementation of environmental protection equipment life cycle management, to ensure the quality of environmental protection equipment built up strong and system security.

From the research on prevention, promotion and application of top-down design, error prevention design, advanced quality planning, influence and harmfulness analysis of failure mode, etc, to a large extent from the source to eliminate hidden dangers, reduce the number of problems, to avoid bigger problems, improve the quality of environmental protection equipment features, fundamentally guarantee the intrinsic characteristics of environmental protection equipment with high quality.

Production capacity is enough

Shanxi Manufacturing Base has invested 280 million yuan, built 14000m² workshop and supporting equipment, 6000m² office, and added 80 sets of equipment (sets), including 10 sets of the most advanced and largest vertical sawing machines in China, 15 sets of 3-32 tons truss cars and supporting equipment, 30 sets of lathes, 6 sets of bending machines, 5 sets of bending machines, and 40 sets of welding machines. There are more than 200 workers on the production line. The production line has large capacity and high efficiency. The whole process adopts intelligent machine platform for distribution, which can meet the product supply needs of large or emergency projects.

Intelligent management

The whole process of production adopts data monitoring, and all parts can be traced to realize the monitoring of equipment quality process and traceability of problems.

Price advantage

Price advantage: standardized equipment, large-scale production, greatly reduce the production cost of RTO, CO, RCO and other environmental protection core equipment, improve the economy of various projects using RTO process.

According to the customer's requirements, using existing equipment to process, and then manual assembly, this makes non-standard environmental protection equipment quality control work is very challenging. Because there is no unified national standard for non-standard environmental protection equipment, it completely relies on the information provided by customers for design and production, which requires as much as possible to obtain detailed information, including specific technical parameters and requirements for accuracy. During this period, we should also prepare the corresponding equipment, debug it, and ensure its good working condition.

03 Project Site Installation

The assembly of equipment starts from component assembly, and the precision of component assembly directly affects the final installation precision of equipment. Parts should be cleaned and equipped with necessary assembly tools. The external environment of assembly should also be cleaned. Important parts should be assembled in a constant temperature environment when necessary to ensure the accuracy of component assembly.

After the overall assembly of the equipment, confirm the assembly quality of the environmental protection equipment, test the overall assembly accuracy of the equipment, and check whether the equipment fully meets the technical requirements.

Actively communicate with customers about the problems existing in the process of using the product, give feedback to customers about the problems of using and maintaining the product in the first time, and make continuous improvement as reference materials for similar products to enhance users' experience of using the product.