TOP

TOPRelated Products

Related Cases

Wet electric and wet dust removal project of Steel slag of Hebei Handan Zhongban Steel Mill

Shanxi Hongda steel slag wet electric Dust removal project

Shanghai Bulannuo Industrial packaging materials online monitoring project

China Tobacco Ningxia Hongde VOCs exhaust gas treatment project

Shanghai Hengjie Wood Industry VOCs waste gas treatment project

Pingyao Paper Mill desulfurization, denitration and dust removal EPC project

Analysis of two - chamber RTO waste gas treatment

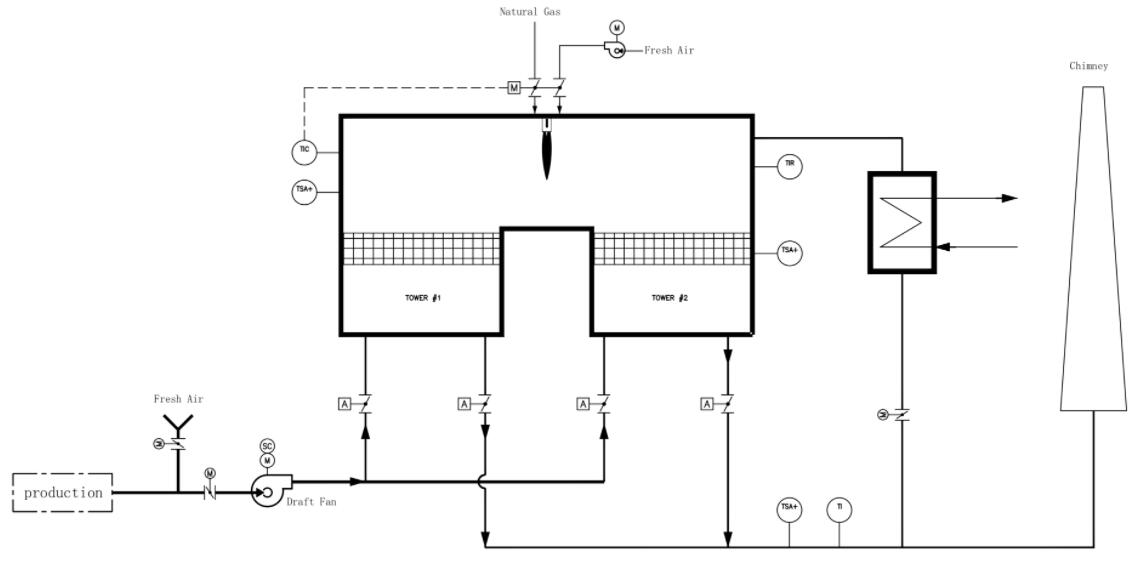

Two-chamber RTO is a kind of RTO incinerator, which is widely used because of its advantages of high waste gas treatment rate and high degree of automation. Here is a simple analysis of the exhaust gas treatment of the two-chamber RTO.

How the two-compartment RTO works:

To be processed in the low temperature exhaust gas by induced draft fan into the regenerative chamber A, ceramic regenerator heat temperature is reduced, and the organic waste gas into the oxidation chamber after rose to A high temperature, burner burning the calories in the oxidation of room, make the oxidation of waste gas to set temperature (760 ℃), the organic compounds in the waste gas is broken down into carbon dioxide and water. Since the exhaust gas has been preheated in the regenerator chamber, the amount of added fuel is less.

The high temperature exhaust gas after purification leaves the oxidation chamber and enters regenerator B to release heat. After the temperature decreases, the exhaust fan is discharged into the air through the chimney. The ceramic regenerator in regenerator B absorbs heat and stores a large amount of heat (for the next cycle to heat the exhaust gas).

After one cycle, the inlet and outlet valves switch once to change the direction of the flow (into the next cycle). Exhaust gas enters from regenerator B, and the purified gas is discharged from regenerator A. And so it goes on and on.

Features of a two-compartment RTO:

1. capacity: 1500 ~ 50000m³/h;

2. The processing efficiency can reach 95%;

3. Higher heat transfer efficiency of 95%;

4. high degree of automation.

After continuous development of RTO incinerator, there have been three chamber RTO, multi-chamber RTO, rotary RTO and so on. It is believed that more RTO equipment will be developed in the future for waste gas treatment and make more contributions to environmental protection.

Lihuang environment is a VOCs management field of domestic companies, has been engaged in industrial waste gas treatment engineering design and equipment manufacturing, has a wealth of theoretical and practical experience. Lihuang environment from the early import RTO furnace installation business began, developed to RTO furnace OEM processing, RTO furnace, RTO rotary tangential valve, high temperature air valve, catalytic combustion, direct combustion furnace and other complete equipment development, has developed into combustion method based on VOCs treatment solutions integrated supplier. The company develops step by step, absorbing innovation, and has obtained a number of patents and qualifications.