TOP

TOPRelated Products

Related Cases

Wet electric and wet dust removal project of Steel slag of Hebei Handan Zhongban Steel Mill

Shanxi Hongda steel slag wet electric Dust removal project

Shanghai Bulannuo Industrial packaging materials online monitoring project

China Tobacco Ningxia Hongde VOCs exhaust gas treatment project

Shanghai Hengjie Wood Industry VOCs waste gas treatment project

Pingyao Paper Mill desulfurization, denitration and dust removal EPC project

How to clean the runner after blockage?

1, the brush

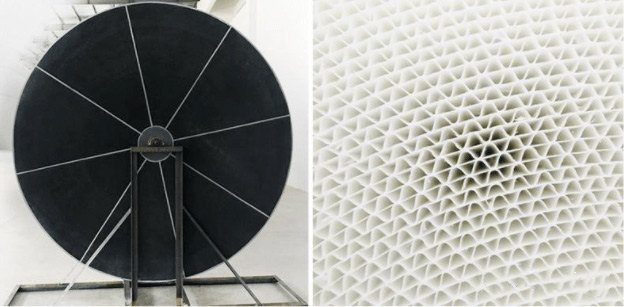

Through field observation, the screen hole of the runner is similar to a triangular array with a side length of 3 mm and a wall thickness of 0.5mm. The adhesion between the plug and the runner is relatively less than the structural strength of the mesh structure itself. The nylon bundle with a diameter of 0.3 ~0.5 mm can be used to puncture the surface of the runner vertically to destroy the bond between the plug and the runner's hole wall. Make the plug away from the wheel without damaging the wheel structure. In order to improve efficiency, the flat brush on site is transformed into a drum type, equipped with a handle. The operator on site can change the flat beating action to the surface rolling action of the wheel, which improves efficiency and reduces the damage to the wheel.

2, compressed air blowing

Field equipment daily use of compressed air, the highest pressure is 0.8mpa, due to the blockage and runner attached more closely, direct use of compressed air purging can only blow out a small amount of blockage, the effect is not good.

3, brush and compressed air combination

On site, brush and compressed air are combined to clean the runner, which is divided into three steps:

1) Roll the surface of the wheel with a brush until the adhesion between the plug and the wheel is broken. Do not use the brush on the wheel lateral friction, so as not to damage the wheel.

2) Blow the runner from the opposite direction with compressed air. The pressure of compressed air is set according to the actual endurance of the runner. In principle, the greater the better under the premise of not damaging the runner.

3) Deep cleaning is carried out before and after the filter box and the runner to avoid the blockage that is cleaned out from entering the runner again. The pressure difference of the runner is reduced from 2000Pa to about 800Pa, and the efficiency of the runner is increased to 98%.