TOP

TOPRelated Products

Related Cases

Wet electric and wet dust removal project of Steel slag of Hebei Handan Zhongban Steel Mill

Shanxi Hongda steel slag wet electric Dust removal project

Shanghai Bulannuo Industrial packaging materials online monitoring project

China Tobacco Ningxia Hongde VOCs exhaust gas treatment project

Shanghai Hengjie Wood Industry VOCs waste gas treatment project

Pingyao Paper Mill desulfurization, denitration and dust removal EPC project

Key points of use of heat accumulator in RTO system

Heat accumulator is the core unit of RTO (regenerative incinerator) to realize heat storage function, which plays a crucial role in the whole RTO equipment. As a core unit, what is the specific function of the heat accumulator and what material should be used? What are the considerations in the application process? Let's find out!

01PART Function of heat accumulator

The function of the heat accumulator is to act as a heat exchanger -- its function is: when the cold waste gas passes through the hot heat accumulator, the heat accumulator releases the stored heat, so that the waste gas is heated to the required preheating temperature and the heat accumulator itself is cooled (cold period); The preheated gas enters the combustion chamber, and after the reaction, the hot purification gas passes through the cold heat accumulator, which absorbs the heat of the purification gas, so that the gas cools and the heat accumulator itself is heated (thermal cycle).

02PART Material selection of regenerative body

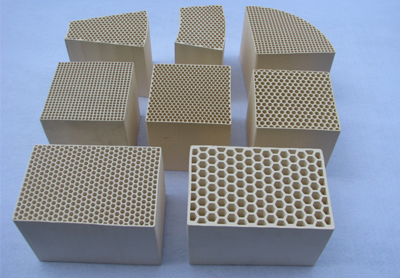

Ceramic heat accumulator

Generally speaking, the materials of heat storage are mainly ceramic and metal. Metal heat storage, such as steel and aluminum, can only be used in low or medium temperature occasions. The RTO unit operates at a higher temperature, so metal materials cannot be used; And ceramic materials have excellent high temperature resistance, oxidation resistance, corrosion resistance and other characteristics, as well as good mechanical strength, cheap and other advantages, performance to meet the requirements of RTO equipment, so currently RTO generally use ceramic materials as heat storage.

The commonly used regenerators include bulk materials (granular packing, such as saddle ring) and structured packing (such as honeycomb packing and plate corrugated packing). In order to reduce the resistance of the bed, most of the structured fillers are used in THE RTO device at present, especially the honeycomb ceramic heat accumulator. Compared with other heat accumulators (such as ceramic balls), honeycomb ceramic heat accumulator has the characteristics of large specific surface area, small resistance loss, small thermal expansion and contraction coefficient, and good thermal resistance. Ceramic honeycomb packing is generally made into a cylindrical regenerative body with a size of 150mm×150mm×150mm or 150mm×150mm×300mm, and built in the regenerative chamber of RTO.

03PARTCaution in using heat accumulators

(1) In the selection of ceramic honeycomb materials, we should not blindly pursue aluminum content. The higher the aluminum content, the higher the fire resistance, but the worse the thermal shock resistance. It is better to use two kinds of materials in the same regenerative chamber. Corundum, mullite and cordierite (or similar materials) are successively adopted from the direction of the furnace to the direction of the furnace, so as to achieve the best optimization of thermal shock resistance and refractoriness.

(2) In actual production, the air-fuel ratio should be strictly controlled to reduce the oxidation burning loss of billet and control the production of ferrous oxide, so as to prevent ferrous oxide from being sucked into the regenerative burner and causing damage to honeycomb.

(3) Incomplete combustion of natural gas will carry out secondary combustion in the regenerative body, resulting in damage to the honeycomb body. When designing the burner, the Angle, distance and momentum ratio of the two jets should be fully considered. At the same time, the air-fuel ratio is controlled to ensure the complete combustion of natural gas. In this way, there is no problem of secondary combustion inside the honeycomb.

(4) the selection of ceramic honeycomb hole spacing and wall thickness should be appropriate. The hole adopts two forms, the first layer near the furnace adopts the large-hole thick wall structure, and the rest adopts the small-hole thin wall structure. In order to pursue large specific surface area, we can not choose too small pore structure, which will affect the strength and easy to plug. There are some gaps (arc connection) between each layer of honeycomb body to smooth the air flow and avoid dust blockage. According to the size of hole spacing and wall thickness to choose the appropriate reversing time. Longer reversing time is beneficial to the service life of key equipment such as reversing valve.