TOP

TOPThis section describes the countermeasures for the safe operation of RTO devices

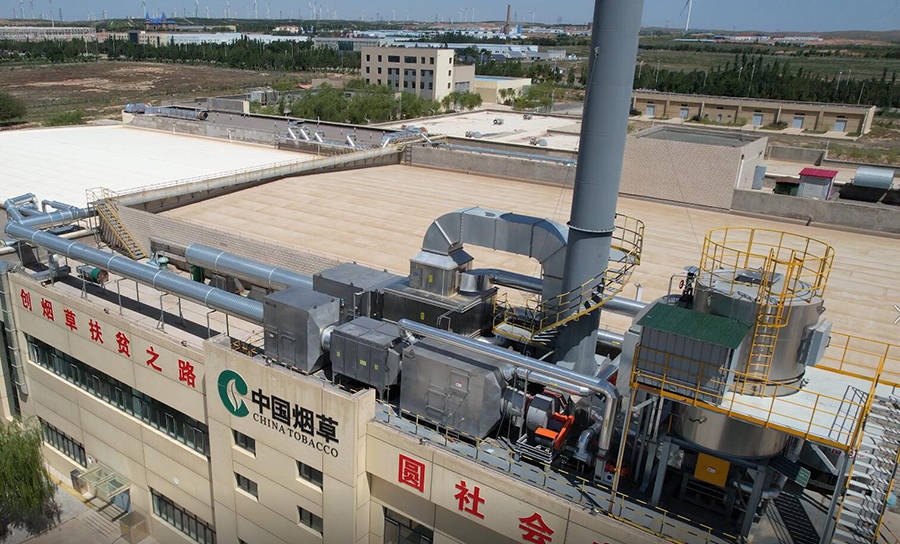

RTO stands for regenerative incineration treatment of organic waste gas. The bulk of the processing process of VOCs in the market now, such as membrane separation, adsorption, absorption, high boiling point solution bioconversion, condensate recovery and thermal oxidation method, such as regenerator furnace thermal oxidation (RTO) has high removal efficiency, economy, applicability, and heat energy utilization efficiency is about 70% higher than that of traditional oxidation direct-fired furnace etc, It is an effective means for enterprises to solve VOCs.

However, the application of RTO also has limitations due to the different conditions of different enterprises. When put into production, production safety accidents have occurred due to operation errors, equipment defects, too small air volume designed for treatment, insufficient timely sediment cleaning, unreasonable collection system design and other reasons.

Measures for safe operation of RTO equipment

I. Collect data and strictly establish the safety design of RTO

According to the requirements of "Engineering Technical Specification for Industrial Organic Waste Gas Treatment by Regenerative Combustion Method" (HJ 1093 -- 2020), the raw materials such as physical and chemical properties of industrial organic waste gas collected by RTO suppliers shall at least include:

1. Exhaust air volume (normal value, maximum value, minimum value);

2. Exhaust gas temperature (normal value, maximum value, minimum value);

3. Exhaust gas pressure, humidity and oxygen content;

4. VOCs composition and concentration in exhaust gas (normal value, maximum value and minimum value);

5. The composition and concentration of inorganic gases in waste gas (normal value, maximum value and minimum value);

6. Concentration of particulate matter in exhaust gas;

7. Pollutant producing equipment and working system;

8. Exhaust emission mode (continuous, intermittent, fluctuation cycle).

Design RTO main body and auxiliary engineering synchronously, set process control related parameters and safety measures in line with HJ 1093 -- 2020 requirements, improve the logic control relationship between main body and auxiliary engineering (exhaust gas collection system pressure, combustible gas detection signal, fuel oil (gas) pressure, instrument gas source pressure, electricity, etc.). Realize the whole system program control.

The RTO furnace system should be included in the safety risk identification of the whole plant and the safety risk assessment demonstration of the whole plant. For the complex exhaust gas composition, HAZOP analysis should be carried out and corresponding safety measures should be taken. Before the acceptance or delivery of the RTO management facilities, the enterprise must pass a third-party professional organization to carry out safety evaluation or relevant identification.

2. improve the current operation of RTO program control, interlocking system

To analysis of combustible gas detector signal, fuel oil (gas) pressure signal, compressed air pressure signal into RTO and normal putting-in-service proactively related logic program control system, perfect the procedure of the program control valve control signal power, gas, and strictly control the concentration of combustible gas should be lower than the most explosive component or mixed gas explosion limit lowest lower limit of 25%, Otherwise, air mandatory dilution or direct discharge should be used; After debugging parameters, RTO should be in automatic running state.

3. Enterprises should strengthen RTO operation and maintenance

Compile the safety operation rules and operation management system in line with the actual production conditions of the enterprise, and train the staff on opening, stopping and emergency operation;

Establish maintenance test record, check and maintain the ground line, jumper, flame arrester, acid (alkali) treatment unit, RTO utilities, etc.

At the same time in the overall planning of the production process, avoid the workshop (process) at the same time feeding, while steaming (fine) distillation, resulting in the concentration of organic materials exhaust emissions, as far as possible to maintain the concentration of exhaust gas, gas relatively stable;

Check and calibrate each sensor (such as temperature, pressure, liquid level, pH meter, combustible gas detector, etc.) regularly to ensure that the operation of RTO is under program control;

At present, in the process of operation and use of RTO system, there are defects in the design itself due to the incomplete basic design data. The program control mainly focuses on the RTO body but does not include combustible gas detection signal. There are also safety problems such as fire and explosion due to improper operation and poor management.

conclusion

In the early stage of design, enterprises and RTO suppliers should do a good job in the collection, confirmation and utilization of basic data to improve the level of RTO intrinsically safe design. At the same time, enterprises should strengthen the operation, maintenance and management of RTO to timely eliminate hidden dangers and ensure the safe operation of RTO.

Shanghai Lihuang specializing in the production of rotary RTO, three tower RTO, CO furnace, activated carbon adsorption box, spray tower, steel slag wet dust removal treatment equipment, SNCR denitrification equipment, SCR denitrification equipment, etc., in spraying, chemical, pharmaceutical, rubber and other waste gas treatment has rich experience, welcome industry colleagues consulting and investigation. 86-021-59106016