TOP

TOPTwo/three rooms, rotating RTO popular science knowledge

Regenerative Thermal Oxidizer, or RTO

RTO is one of the most mature, the most stable, the most effective organic waste gas treatment equipment, is also the current VOCs management industry market amount of the largest segment. How many kinds of RTO are there? Here's a look:

RTO operates by heating organic waste gas to temperatures above 760 degrees Celsius, and by controlling temperature, residence time, turbulence and oxygen levels, the VOCs in the waste gas are oxidized and broken down into carbon dioxide and water.

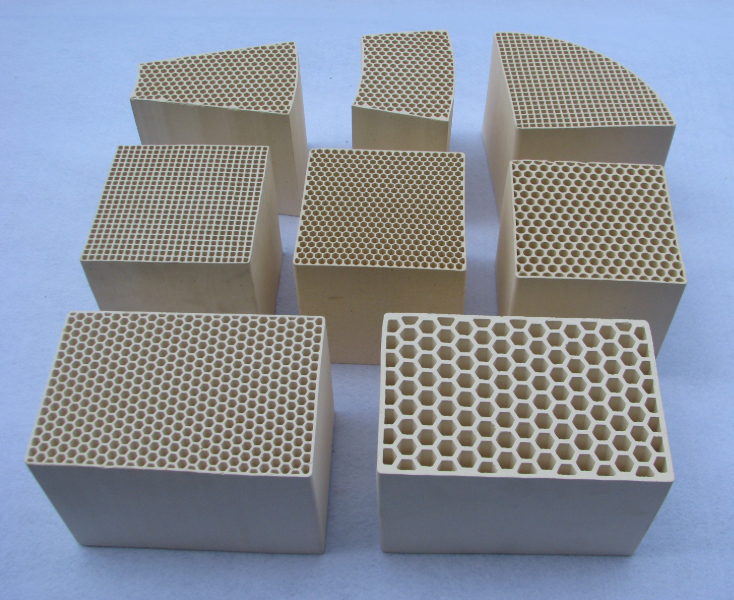

Heat storage, also known as heat storage filler, is an important part of RTO device, usually made of honeycomb ceramic material; It is equivalent to a heat exchanger, the role is: when the cold exhaust gas through the hot heat accumulator, the heat accumulator will be stored heat release, so that the exhaust gas is heated to the required preheating temperature and the heat accumulator itself is cooled (cold cycle); The preheated gas enters the combustion chamber. After the reaction, the hot purification gas passes through the cold heat accumulator. The heat accumulator absorbs the heat of the purification gas, so that the gas is cooled and the heat accumulator itself is heated (thermal cycle).

Ceramic regenerator shall be divided into two or more, each regenerator shall go through the process of heat storage, heat release and cleaning successively.

RTO device can be divided into two chamber RTO, three chamber (multi-chamber)RTO and rotary RTO according to the different structure; The VOCs removal rate of two-chamber RTO device is 95%-98%, the VOCs removal rate of three-chamber RTO device can reach more than 98%, and the rotary RTO removal rate can reach more than 99%.

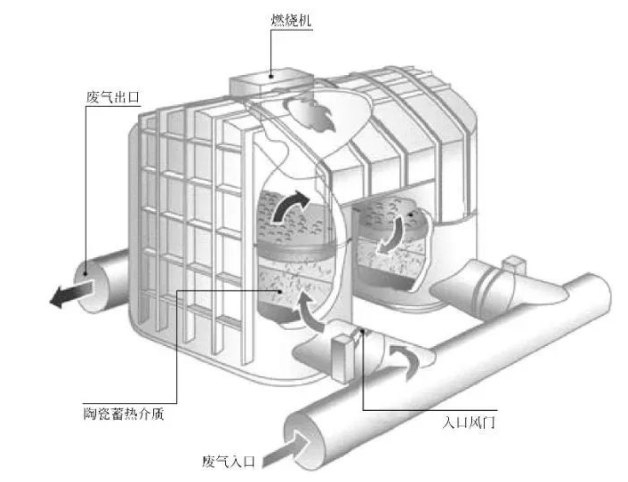

1Two rooms RTO

The organic waste gas is fed into the regenerator 1 through the induced draft fan to heat up, absorb the heat stored in the regenerator, and then enter the combustor for further combustion, heating up to the set temperature. In this process, the organic components are completely decomposed into CO2 and H2O.

Fuel consumption is reduced because the exhaust gas absorbs the heat recovered from the previous cycle in regenerator 1. The treated high temperature exhaust gas enters the regenerator 2 for heat exchange, and the heat is absorbed by the regenerator and then discharged. The heat stored in regenerator 2 will be used to heat the incoming exhaust gas in the next cycle.

After the process is completed, the system automatically switches the inlet and outlet valves to change the flow direction of the exhaust gas, so that the organic exhaust gas enters through regenerator 2, and is discharged by heat exchange in regenerator 1 after incineration treatment, so that the alternating switching continues to operate.

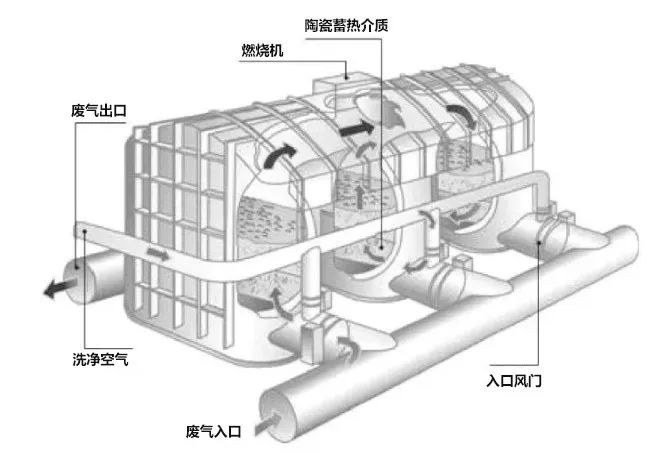

2 3 rooms RTO

The three-chamber RTO device treats waste gas in a similar way to the two-chamber principle, but the difference is that after "heat release" of the three-chamber RTO regenerator, an appropriate amount of clean air should be introduced immediately to clean the regenerator (to ensure that the VOC removal rate is above 98%), and the "heat storage" procedure can be entered only after cleaning is completed. Otherwise, the residual VOCs are discharged to the chimney with the flue gas, thereby reducing the treatment efficiency.

3 Rotary RTO

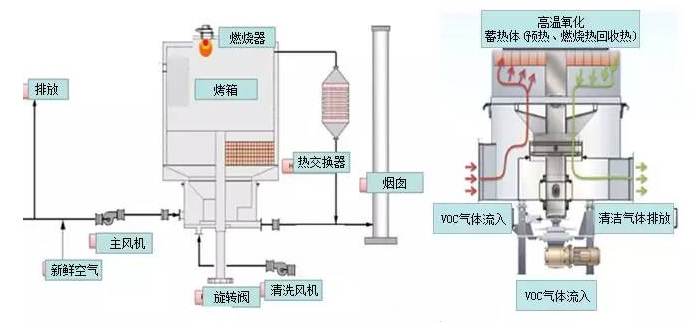

Flow chart of rotary RTO processing

Rotary RTO is mainly composed of combustion chamber, ceramic packed bed and rotary valve. The furnace body is divided into 12 chambers, 5 chambers for exhaust gas, 5 chambers for purification, 1 chamber for cleaning, and 1 chamber for isolation. The exhaust gas distribution valve is rotated continuously and uniformly by the motor. Under the action of the distribution valve, the exhaust gas slowly switches between the 12 chambers continuously.

There are 12 heat accumulators in the heat storage layer to supply gas and discharge. Five of the 12 heat accumulators are for the inlet, five in the opposite direction are for the outlet, and one of the remaining two is for cleaning.

RTO exhaust gas treatment equipment is suitable for high concentration organic waste gas, coating waste gas, odor waste gas and other waste gas purification treatment; It is suitable for the exhaust gas composition often changes or the exhaust gas contains ingredients that make the catalyst toxic or active decline (such as mercury, tin, zinc and other metal vapor and phosphorus, phosphide, arsenic, etc., easy to make the catalyst lose activity; Containing halogen and large amounts of water vapor), containing halogen hydrocarbons and other corrosive organic gases.

As a mainstream VOC treatment process, RTO equipment has many advantages that make it stand out:

1, RTO exhaust gas treatment equipment can deal with almost all the waste gas containing organic compounds, can deal with large air volume, low concentration of organic waste gas. The flow rate of organic waste gas is very elastic (nominal flow rate 20% ~ 120%).

2, RTO waste gas treatment equipment can adapt to the composition and concentration of VOCs in organic waste gas changes, fluctuations, is not sensitive to a small amount of dust, solid particles in the waste gas entrained, in all the thermal combustion purification method of high thermal efficiency (>95%).

3, RTO exhaust gas treatment equipment can achieve self-heating operation without adding auxiliary fuel under the condition of appropriate exhaust gas concentration, with high purification efficiency (three rooms >98%), less maintenance workload, safe and reliable operation. The organic sediment can be removed periodically, the heat accumulator can be replaced, the pressure loss of the whole device is small, the service life of the device is long.